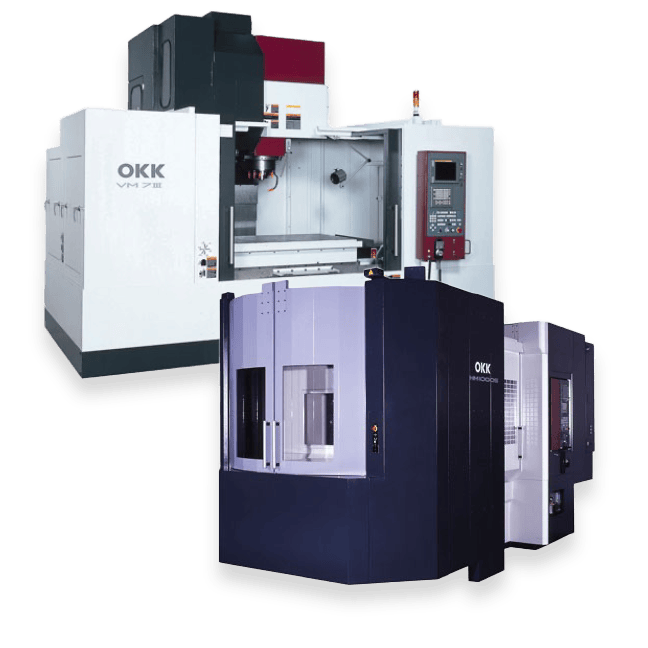

Utilizing state-of-the-art machining software and tooling ensures that machining is completed accurately and efficiently.

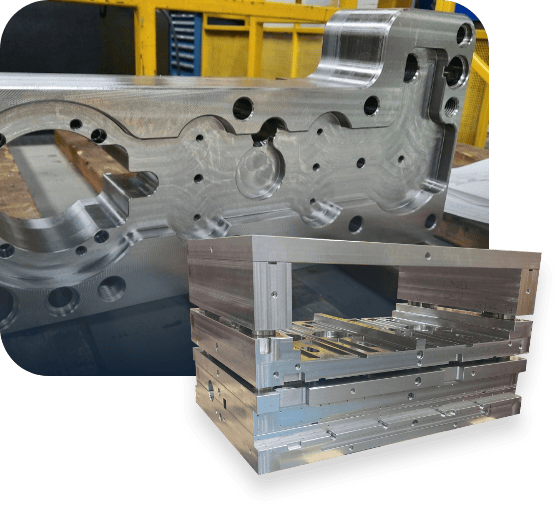

We provide comprehensive product design support, tooling feasibility studies, and Solidworks expertise to ensure the highest level of precision and functionality. Our manufacturing process includes complete quote review and shop floor management with Powermill and Mastercam, ensuring meticulous attention to detail and quality.

Our facility is equipped with advanced technology to meet the diverse manufacturing needs of our clients.